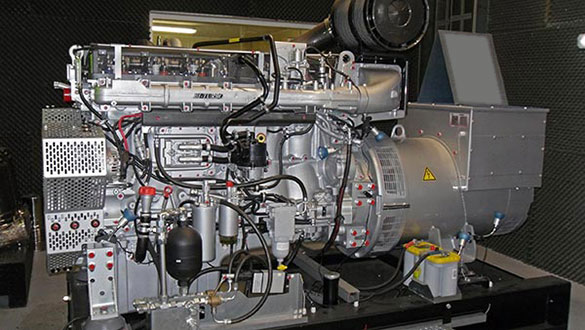

We offer efficient exhaust treatment systems for everything from small construction site power generators to larger systems in containers, emergency power systems or emergency power generators.

The high percentage of components we manufacture in-house allows us to offer solutions for engines with power ratings ranging from 20 kW to multiple MW.

Our wide range of products with a variety of particulate filter systems with both active and passive regeneration, as well as our T-blue NOx Reduction System and oxidation catalytic converters allow us to choose the perfect exhaust treatment components for practically any application.

With more than 25 years of experience, we are able to meet requirements for generator operation on construction sites with the lowest possible emissions while also complying with the threshold values of TA Luft for the operation of stationary emergency power systems and generators.

Naturally, all exhaust treatment systems that are designed and manufactured by TEHAG comply with stringent approval criteria. This means, for example, that all TEHAG particulate filter systems are tested in accordance with the specifications laid out by the VERT® Association, comply with the Swiss LRV directive, and have, in part, received general operating permits from the German Federal Motor Transport Authority.

By using our soot particle filter systems, not only particle reduction but also gaseous pollutants such as carbon monoxide and hydrocarbons are reduced up to the detection limit. Thus, legal regulations of TA Luft and TRGS 554 can also be achieved and complied with in older existing plants.

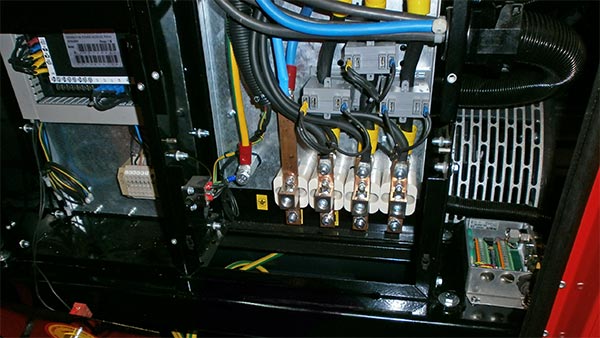

When you combine a TEHAG particulate filter system with a T-blue NOx Reduction System, you can sustainably reduce all legally regulated emission groups found in diesel exhaust.

Not least due to the restructuring of TA Luft and the introduction of regional clean-air plans, the renewal of operating licences for engine test benches is becoming increasingly dependent on compliance with the corresponding emission limits for particulate matter (PM), carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx). These regulations affect not only new projects, but also existing engine test benches.

Luckily, we offer efficient exhaust treatment systems for these applications that allow you to comply with emission limits and regional clean air requirements. Our particulate filters and our T-blue NOx Reduction System are ideal for equipping engine test benches. Our success speaks for itself: we have successfully completed countless projects in this area over the past few years.

We also offer you a variety of catalytic converters for the reduction of CO, HC and NOx during operation of petrol and diesel motors, as well as slip catalysts to minimise gas slip.

You can find more information along with request forms in our downloads area.

If so, please call us or send us an email! Our competent team will be there to assist you throughout.